A CNC touch screen is a type of computer monitor that changes the way you interact with an automated machine tool. You use the whole screen as a kind of touch-sensitive tablet, pressing buttons or various menus to tell this machine what to do without having to sit with keyboard and mouse. In addition to the ease of use, this saves space and makes it an excellent choice for many industries. A person with disabilities can take advantage of the convenience and accessibility that a CNC touch screen offers.

A great advancement of computer-aided manufacturing (CAM) are the CNC touch screens. These touch screens leverage real-world software and hardware tools like high resolution displays and intuitive user interfaces to create a superior environment for quickly implementing functional users. Operators can easily produce intricate parts and material now, with hassle-less interaction of CNC machines.

For operators one of the key advantage to using CNC touch screens is a significant increase in safety. Instead of using a keyboard or mouse to input commands like traditional CNC machines, touch screens are able to allow operators to input commands from one screen. This will not only help to reduce the risk of injuries but also decrease any potential errors that can happen with manual inputs.

Operating a CNC touch screen is simple and user-friendly. It's very easy to use, with operators selecting from a huge array of menus and functions simply by touching different parts of the screen. With the touch screen software users can easily select tools, change machine speed and monitor progress in real-time. Operators may also save different settings and configurations to streamline the process of repeating successful operations.

CNC Operator-Operators must have basic computer skills to use the CNC touch screen,to get through basics for moving feeds up / down, feed selecting in menus. Understanding the buttons and features of the touch screen will be crucial for anyone working on a CNC machine, if only because it communicates with you through them. Also learn about touch screen settings and configuration such as custom tool profiles, axis configurations to ensure you get the best performance.

If you want to use a hand-held touch screen table, it is very important that the manufacturer or supplier provides quality service and support as well. Continuous technical support, regular machine maintenance programs and access to training resources can help the operators in better utilizing the touch screen. Finally, an all-encompassing warranty and a good return policy will be signs of the best supplier.

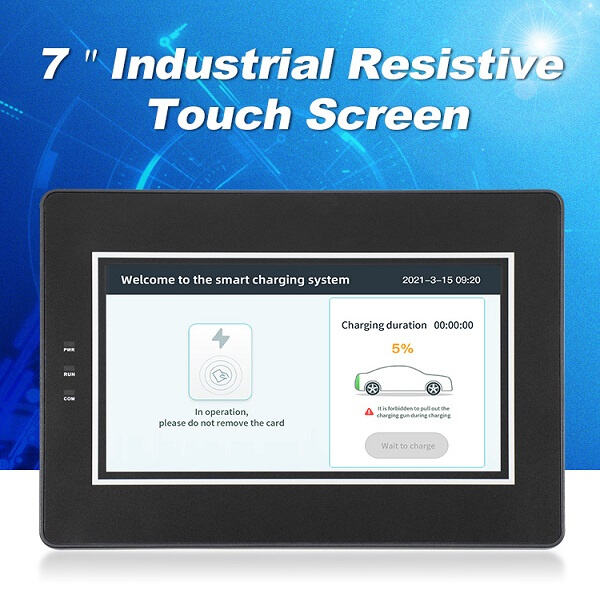

Quality matters the most when it comes to selecting a CNC touch screen. This demonstrates the durability and accurate touch sensing capability these top-quality screens have even after years of constant use. On the other side, it needs to be compatible with a variety of CNC machines and different software platforms. Top quality touch screens may also includes some advanced features such as anti-glare screen and ambient light sensor.

Applications of CNC touch screens range from automotive to aerospace and technology fields. They are especially popular in applications that require exceptional precision machining, including medical device manufacturing and the production of custom parts[]. Furthermore, their cost effective and user-friendly features have only magnified in smaller shops (i.e. hobbyists),which may display the continued trend of CNC touchscreens occupying a larger share within overall manufacturing environments.

A CNC touch screen is a computer monitor that you can use to control a CNC machine. It operates by touching different parts of the screen, such as buttons or menus, to give commands to the machine. One of the most significant benefits of a CNC touch screen is that it reduces the need for a separate keyboard and mouse, making it easier to use and more space-efficient. Additionally, it is an excellent choice for people who may have difficulty using traditional input devices, such as those with disabilities.

CNC touch screens represent a significant innovation in the field of computer-aided manufacturing (CAM). They use the latest software and hardware technologies, including high-resolution displays, capacitive touch sensors, and intuitive user interfaces, to provide a superior user experience. This innovation has revolutionized the way operators interact with CNC machines, making it easier and more efficient to produce complex parts and materials.

Another key benefit of CNC touch screens is that they offer improved safety for operators. Traditional CNC machines typically require users to input commands using a keyboard and mouse, which can be awkward and time-consuming. By contrast, CNC touch screens allow operators to input commands from a single screen, reducing the risk of accidental injuries. Moreover, this input method eliminates the need for manual inputs that can lead to errors.

Using a CNC touch screen is relatively simple and intuitive. Once the screen is installed, operators can access a variety of menus and functions by touching the screen's different areas. For example, they can select various tools, adjust the machine's speed and feed rates, and monitor the machine's progress in real-time. Additionally, the touch screen software allows operators to save and store different settings and configurations, making it easier to repeat successful operations.

Huaqingjun a world-class manufacturer industrial control. Our company, after 20 years of cnc touch screen, has grown to 3000sqms large-scale enterprise that focuses on production development sale of Internet Things. At the same time, company a highly skilled R D department which can offer technical solutions for our customers. Our company also provides 4G module, Ethernet modules, WIFI modules, Bluetooth Modules, Simple Programmable PLC Integrated Machines, RS485 Communication Modules Industrial Relay Modules PLC AC/DC Power Amplifier modules and other products that are core to our business.

product development has secured many patents. company has been awarded distinctions like "National High-tech Expertise", "Guangdong Province Contract-abiding Enterprise" "Creditworthy Enterprise". The products have been accredited by the "IS09001-2015 quality certification" and have also been able to pass other certifications, such as FCC and CE. The company gathered large number of experienced R D talents with backgrounds in professional academics such as electronic engineering, cnc touch screen engineering communication engineering, and more. team of experts works closely with their customers improve the overall experience for customers. They also serve large numbers of companies as well as manufacturers equipment. We create more competitive industrial solutions our customers. company has a highly skilled intelligent production facility. All products come with solid and well-established chips that guarantee top performance. Customers are able to use and buy with confidence.

There variety applications consider parking system, greenhouse ETC induction system traffic lights system streetlamps control smart home systems water spray control, fire alarm system, HVAC SCADA, remote controls. There a myriad uses such as parking system. greenhouse, ETC Induction, packaging system. traffic lighting system. streetlamp control. smart home system. Robot control. water spray control. The cnc touch screen line comes with an advanced SMT mounter, automated wave soldering, fully automated packaging machine a full collection high-quality inspection equipment to make sure that every product produced is "carefully skillfully created", that customers can buy use with confidence. We can also provide solutions specifically designed to our clients' requirements.

The company holds number of patents in the national system and has also won awards like "National High-Tech Expertise", "Guangdong Province Contract and Credit-abiding Business", "Guangdong Province Contract and Credit-abiding Company". The cnc touch screen have passed "IS09001: 2015 Quality Certification". product has also received CE, ROHS, FCC, SGS etc. certifications. The company has also gathered many experienced R D experts education automation, electronic engineering, communication engineering, and many more. The experienced team devoted to end customers, continuously improves customer experience, and serves majority Internet Things companies and equipment manufacturing companies.

To use a CNC touch screen effectively, operators need to have basic computer skills, such as being able to navigate menus and select different options. However, once they become familiar with the touch screen's layout and features, they will find it much easier to operate the CNC machine. Operators should also take time to learn about the various settings and configurations available on the touch screen, such as custom tool profiles and axis configurations.

When purchasing a CNC touch screen, it is essential to consider the quality of the service and support provided by the manufacturer or supplier. Good service should include ongoing technical support, maintenance programs, and training resources to help operators use the touch screen effectively. Additionally, the supplier should offer a comprehensive warranty and return policy.

Finally, the quality of the CNC touch screen itself is crucial. A high-quality touch screen should offer exceptional durability, accuracy, and responsiveness, even under heavy use. Additionally, the touch screen should be compatible with a wide range of CNC machines and software platforms. Good quality touch screens may also offer additional features, such as anti-glare screens or ambient light sensors.