Modbus 485 inputs are a vital part of maintaining efficient processes within the industrial automation sphere. These are the important components which collect the useful information from various instruments that exist in an industrial unit. One of the most common communication protocols, Modbus allows devices to talk with each other while '485' in this context means that it is specifically talking about the type of wiring. Modbus 485 inputs are used to export data that will be uploaded into a central processing and analysis unit.

One of the most important processes in industrial automation is data acquisition, and Modbus 485 inputs perform a key role through this process. All the above inputs are useful to access good amount of data from different instruments that can be used to monitor and control various processes in industrial system. Those inputs are already integrated functionally in the sense that they relay signals to instruments and gather back relevant information. The data is used to make system operations better, then resulting in a more efficient turn-around.

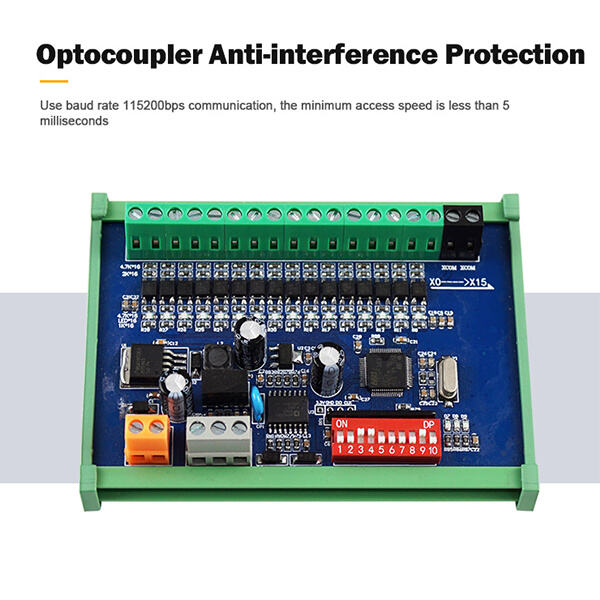

Wiring of connections and Modbus 485 inputs is a bit complex but following these guidelines can simplify this. First, the inputs need to be hooked up to each instrument with a proper wiring infrastructure. The inputs then need to be tuned, usually in data rate settings and possibly alterations for parity and stop bits at the source instrumentation. Lastly, it is necessary to incorporate the inputs into the software of central device for smooth data-capture and processing.

If you want to get the benefits that Modbus 485 inputs offer within your industrial applications, it is important to utilize them properly. This includes data acquisition software and setting up the inputs correctly, but also using that collected information to take tools like CFD results/studies as far into transitioning from simulation/analysis only based understanding of system performance over toward more practical reality-based decision-making process about our system. Further, it is very important to keep the wires and connections in proper order so as not let any issues or faults arise.

However, just like any other tech system Modbus 485 inputs too could face glitches that require worming out. A common problem is communication issues, typically due to misconfigured settings or bad wiring. Solving this kind of problems implies to check everything in the system, so all components are properly installed and if you have a correct continuity on wiring. Also, software associated issues, such as errors in data acquisition or handling can normally be resolved with close scrutiny and updating of the program

Our product development secured numerous patents. It also won honors such as "National Expertise in High-Tech" Guangdong Province contract-abiding and creditworthy Enterprise". products have been certified by the "IS09001-2015 quality certification" as well as various other certifications including the FCC and CE. The company has collected an array RD talent who possess academic qualifications in automation, electronic engineering communication, as well as other fields. team professionals work closely with customers enhance their overall experience for customers. They also support the majority companies and manufacturers of modbus 485 inputs. Our customers enjoy higher-quality solutions for industry. Furthermore, the business has a professional intelligent production facility. All products come with solid and well-established chips that ensure excellent performance. Customers able to use and purchase with confidence.

Huaqingjun a leading producer of modbus 485 inputs control. With 20 years development, business has developed into large scale enterprise of 3000sqms that is focused on development, production and selling of Internet of Things. Our company also has an R D department that provides technical solutions customers. company also offers 4G module, Ethernet modules, WIFI modules, Bluetooth Modules, Simple Programmable PLC Integrated Machines RS485 Communication Modules Industrial Relay Modules PLC AC/DC Power Amplifier Modules and other core products.

The company holds number of national patents and has won distinctions such as "National High Technology Expertise", "Guangdong Province Contract Credit-abiding Business" as well as "Guangdong Province Contract and Credit-abiding Corporation". The products have been certified "IS09001 Quality: 2015 Certification". product is approved by CE, ROHS FCC SGS and other. certifications. company has also gathered an impressive pool R D professional with academic backgrounds in automation, electronics engineering, and modbus 485 inputs engineering. team dedicated to serving end users, improving customer service, collaborating with majority Internet Things equipment manufacturing companies.

products comprise RS485 The products of RS485 232 Ethernet modules and analog inputs modules PLC, analog outputs module, HMI, relay module, AC/DC amplifier board as well as switching power supply. There are numerous applications parking systems, such as. The greenhouse ETC Induction, packaging system. modbus 485 inputs lighting system. streetlamp control. smart home system. Robot control. Control of water spray. The production line features SMT mounter equipped with automatic wave soldering automated packaging machines. The line also comes with complete set of quality control equipment. This ensures that each product is produced "carefully and professionally" to allow customers to buy and use the product with confidence. We are able to provide various options to meet the needs of the systems of our customers.