In addition, among various industrial automation application fields communication protocols plays a role of "secret language," to realize the community between numerous devices and systems in terms field. Modbus RTU over RS-485 is a very important protocol in this field. It is one of the oldest and works across devices of many manufacturers - a testament to its longevity, simplicity and reliability. The Modbus 485 IO module plays a vital role in facilitating communication between field devices and control systems by creating the core of this protocol. Extensions of this module are developing along more and new applications as technology bias ahead making the future industrial automation move toward smart factories.

In the future, Modbus RTU 485 IO modules will be very locked with development in technology like IoT (Internet of things), Industry 4.0 and edge computing. As these modules more powerful, it's no wonder that they are also adding in better data processing capabilities and upping their game on security plus supporting wireless connectivity. IoT-enabled modules make it possible for industries to finally be able monitor remotely their machines and do some predictive maintenance would allows them reduce through downtimes, liberates operational efficiency. In addition, AI and machine learning algorithms will be the part of these modules instead that can change decision making in industrial systems.

Embracing Modbus 485 IO modules can greatly simplify automation in industries. For the exchange and control of real-time data between sensors, actuators, Programmable Logic Controllers (PLCs), SCADA systems these modules make an easy job to communicate. This not only speeds up system responses but also helps in the quick deployment and maintenance of intricate automation networks. The protocol is deterministic due to the master-slave architecture, a key feature in operations where timing and synchronization are critical. At the end of the day, Modbus 485 IO modules enable businesses to streamline production flows & improve product quality while driving down operational costs.

This is nothing less than a model of how industrial control systems look.Modbus 485 IO modules. Up to 247 devices on a single serial lineThe possibility of connecting up to 247 nodes from the same CAN bus simplifies and cuts costs in case traditional point-to-point wiring is located at hand. Additionally, because Modbus RTU is so pervasive in the market for field buses, devices from different manufacturers can interact with one another as need be based on this legacy protocol-providing a robust and flexible solution to prevent vendor lock-in down the line. Thanks to their modular, robust nature and ease of implementation, these modules have become irreplaceable in a range of industries from manufacturing & energy management through Heating, Ventilation & Air Conditioning (HVAC) to building automation proving that this was indeed revolutionary technology.

If you have a smart factory, one of the best things that you can do is to select right Modbus 485 IO module. Primary considerations should be the I/O count (number and type of Input/Output points required: digital, analog or both) as well as environmental conditions (temperature range, humidity rating, vibration resistance), advanced features such isolation capability from noise coming over common grounds on adjacent devices, surge protection for dirty power inlets that may harm your main control device/engine -- aside all basic operational breakdown things with help debugging through diagnostics tools provided by selected brand/model units supporting these options -such upgrades could improve own troubleshooting capabilities while reducing downtimes/errors yield). This does not take into consideration the type of power required by module, it makes one ignore form factor and ability to integrate with existing hardware/software infrastructure. You also want to make sure that the selected solution matches with how you hope your automation needs will mature into longer-term objectives which perhaps drives a scalable approach or upgrade path.

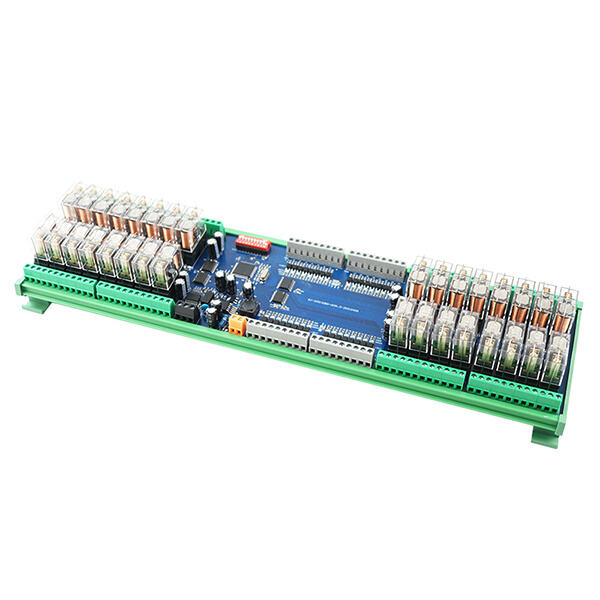

The products comprise RS485 the 232 Ethernet modules analog inputs modules analog outputs module, PLC HMI, relay module, AC/DC amplifier board Switching power supply, etc. There are a variety of applications for parking systems, such as. The greenhouse ETC Induction, packaging system. traffic lights system. streetlamps control. Smart home automation. Robot control. Water spray control. The production has a SMT mounter is modbus 485 io module automated wave soldering automated packaging machines. line also comes with an entire set of top-quality control equipment. This makes sure that each product produced "carefully and professionally" so customers can buy and use it with confidence. We can also provide a variety solutions our customers' systems.

Patents have been granted for the product's development. company has won distinctions like "National High-tech Expertise", "Guangdong Province Contract-abiding Enterprise" as well "Creditworthy Enterprise". The products have also passed "IS09001:2015 quality certification" have also been certified by the FCC, CE, ROHS, ISO and other certifications. The company has collected many R D modbus 485 io module who academically trained fields electronic engineering, automation communications, and other areas. The team of experts is dedicated to the end customers, continuously enhances customer service, and supports majority of IOT companies and equipment manufacturing companies. customers benefit from better solutions that are competitive in the market. company has a highly skilled manufacturing facility that is highly efficient. Each product is equipped with robust and stable chips that provide excellent performance. Customers are able to use purchase with confidence.

The company holds number of patents in the national system and has also won awards like "National High-Tech Expertise", "Guangdong Province Contract and Credit-abiding Business", "Guangdong Province Contract and Credit-abiding Company". The modbus 485 io module have passed "IS09001: 2015 Quality Certification". product has also received CE, ROHS, FCC, SGS etc. certifications. The company has also gathered many experienced R D experts education automation, electronic engineering, communication engineering, and many more. The experienced team devoted to end customers, continuously improves customer experience, and serves majority Internet Things companies and equipment manufacturing companies.

Huaqingjun a world-class manufacturer industrial control. Our company, after 20 years of modbus 485 io module, has grown to 3000sqms large-scale enterprise that focuses on production development sale of Internet Things. At the same time, company a highly skilled R D department which can offer technical solutions for our customers. Our company also provides 4G module, Ethernet modules, WIFI modules, Bluetooth Modules, Simple Programmable PLC Integrated Machines, RS485 Communication Modules Industrial Relay Modules PLC AC/DC Power Amplifier modules and other products that are core to our business.

This is why modern Modbus RTU 485 I/O modules are being developed in a manner that guarantees the transmission of reliable data while supporting security and performance. Utilizing protocol-level error checking and fast communication to support real-time control and data-intensive applications, these modules provide more sophisticated protection mechanisms for the integrity of your precious information. Modern modules also provide improved security measures like encryption and authentication protocols to address the rising need for a cybersecurity solution that prevents both unauthorized access and changes. In addition, the connectivity options to cloud provide functionality for data transfer in real time on a continuous basis - feeding advanced analytics and long-range remote monitoring...supplying businesses with practical insights to enhance their operations. They can take advantage of these cutting-edge solutions to reach unparalleled levels of operational efficiency, responsiveness and resiliency in their automation ecosystems.

In summary, Modbus 485 IO modules are the forefront of industrial automation without them even a thought is not possible regarding intelligent factory. As technology continues to grow the beacons of today will surely become even more evolved and as any session on IIoT or industry 4.0 should discuss, they are already indispensable tools for our times With businesses able to pick and choose which modules they want, working together seamlessly with their existing production processes - this could prove the definitive value-adding solution to manufacturers securing a place in the future.