Modbus is an old communication protocol that had great success in the industrial automation world since long time. It is an important basic block in this field. But an important novelty of Modbus is it can accept analog output that lies at the heart of ensuring precise control and monitoring in many sectors. Modbus - Empowers systems to utilize intricate control schemes with the ability control devices that had been too expensive prior, efficiently managing customer services and ensuring perfect working order. In this article, and to discover the full capabilities of Modbus analog outputs in process improvement workflows, we will explore what a modbus high resolution is (including some relevant information on how it can help enhance automation), its practical setup and potential issues that need addressing for smooth operation; how they already integrate into IoT ecosystems without additional configuration or requirements at your end besides getting them online quickly by following simple manufacturer instructions - making monitoring operations secure from being detected outside home networks due +3 days passaging around public services where most people live now:) You may also want these types look like smart devices as soon possible using open-source software libraries so new applications become available built just ideas you measure anything real life environments predict emergencies ahead time others do not know.

The ability to control certain variables, like temperature, pressure or flow rates with the greatest degree of precision are central ingredients for achieving precision control. Modbus analog outputs are strong here because they send out real values... extracted from 0-20 mA or 4-20 mA, etc. These results to some physical quantity in the actual world. Controllers can use these outputs to issue instructions to actuators, valves or variable speed drives which adjust things like flow rates and dampers in order maintain setpoints. This enables industrial plants to maximize process control, reduce waste and enhance product quality.

A good communication between devices is essential for anywell-planned automation workflows Unifying this communication is the Modbus protocol for analog outputs, providing a common way to transmit an analog signal between all of your gear regardless on vendor. This makes it easier to design systems that are interoperable, streamlining system integration and minimising support costs. Moreover, Modbus analog outputs allow to monitor the process and adjust variables in real-time so that predictive maintenance routines can be set up as soon as a deviation occurs reducing operational downtime on your workflow.

Setting up of Modbus analog outputs require a good understanding about all the address mapping, data calibration and register settings. The digital representation of the analog signal connected with each analog output are saved in some holding registers, which define specific Modbus data-structure. For accurate control, it is essential to scale these values by scaling them with regards the physical range of output device. Frequently associated issues such as a bad configuration, communication failure or hardware fault requires debugging to be approached in an organized manner and diagnostics software helps by observing the data traffic and sanity checking register values. Only by the application of regular uses firmware updates, compatible with common practices guarantees high performance and low susceptibility to single-point failures.

The Internet of Things (IoT), rise has drastically revolutionized industrial automation with Modbus analog outputs being the catalyst in this change. Combining Modbus and IoT platforms makes the analog outputs vital cogs in a rich ecosystem for remote monitoring, control via cloud based services. This combination enables advanced real-time analytics, predictive maintenance approaches and more informed decisions based on big data-derived insights. To make them work together, a gateway or converter is needed to cross over Modbus protocols with the other kinds that IoT things prefer (MQTT and RESTful APIs). With the growing sophistication of potential cybersecurity threats, secure data transmission that needs to be secured and well-protected at every step has become even more important when it comes to protecting sensitive operational data in this interconnected world.

The product develop has been granted numerous patents. Our company has received distinctions like "National High-Tech Expertise", "Guangdong Province Contract-abiding Enterprise", and "Creditworthy Enterprise". The products have been accredited by the "IS09001-2015 quality certification" as well as other certifications such as FCC and CE. The company has brought together a number of R D talents who have academic degrees automation, electronic engineering communication, and many other fields. The team of professionals works closely with the customers enhance the overall experience of customers. They also service large modbus analog output of companies as well as manufacturers equipment. customers enjoy higher-quality solutions the industry. company has highly skilled efficient production facility. products are all equipped with reliable durable chips that ensure high-performance which allows customers to buy and use their products with confidence.

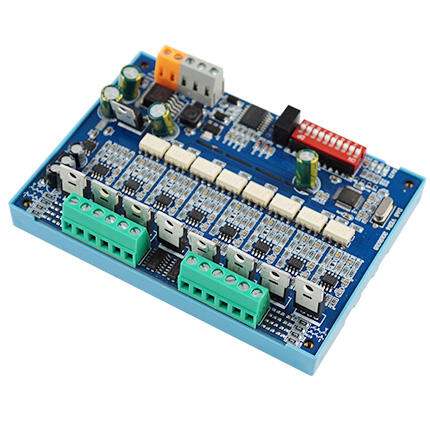

The products include RS485 and 232 Ethernet modules, analog inputs modules, analog outputs module, PLC HMI, relay modules, AC/DC amplifier board and switching power supply. There a variety application that includes parking systems. greenhouse, ETC Induction, packaging system. Traffic lights system. streetlamps control. smart home automation. Robot control. Control of water spray. production line has SMT mounter with automatic wave soldering automated packaging modbus analog output. Also, it comes with an entire set of top-quality control equipment. This ensures each item is manufactured "carefully and with care" which allows customers purchase and utilize it with confidence. We can also provide solutions specifically designed the needs of our customers.

The company holds number of patents in the national system and has also won awards like "National High-Tech Expertise", "Guangdong Province Contract and Credit-abiding Business", "Guangdong Province Contract and Credit-abiding Company". The modbus analog output have passed "IS09001: 2015 Quality Certification". product has also received CE, ROHS, FCC, SGS etc. certifications. The company has also gathered many experienced R D experts education automation, electronic engineering, communication engineering, and many more. The experienced team devoted to end customers, continuously improves customer experience, and serves majority Internet Things companies and equipment manufacturing companies.

Huaqingjun, leading manufacturing company industrial controls. Our company, after 20 years expansion has grown to become a 3000sqms large-scale enterprise that focuses on the production of, development and sale of Internet Things. Our company also has a R D department that provides technological solutions to our customers. company also has 4G module, Ethernet modules, WIFI modules, Bluetooth Modules, Simple modbus analog output PLC integrated machines, RS485 Communication Modules, Industrial Relay Modules, PLC AC/DC Power Amplifier Modules as well as additional core products.

Modbus Analog Outputs have been used in several interesting applications in smart industries due to their versatile nature. For solar and wind, they provide exact control of both the PV sun trackers for maximum energy capture in renewable generation plants as well as integrate them into wind turbine pitch systems. They also boost HVAC systems for more energy efficient and occupant friendly heating, cooling within smart buildings. Pharmaceutical manufacturing is an industry where the particular environmental conditions under which drugs are produced must be kept extremely well controlled and Modbus analog outputs can help you achieve this. However, they are also used to target the delivery of water in precision irrigation spray systems that measure soil moisture levels. More pressingly, analog outputs play an important role in more nuanced motion control and sensory feedback needs of advanced robotics, as well as autonomous vehicles.

In summary, Modbus analog outputs are the cornerstone of industrial automation as we know it today and provide precise control logic operation - streamlining workflow processes with easy integration into IoT ecosystems. With industries adopting digital transformation now more than ever before, the deliberate application of Modbus analog outputs is set to make even greater strides in improving innovation and efficiencies that will push smart industry forward across borders.