Indeed within the industrial process world, systems become more complex and are put under increasing demands. This is the area where automated systems come into play, as they perform a key role in order to keep production running properly and fast. Introduction to PLC Module - A Short GuideAt the core of industrial automation is a module called programmable logic controller (PLC). Industrial control systems are the specialized pieces of equipment that are used to manage and monitor industrial machinery, processes, and facilities. PLC modules are a key element in that regard, allowing different processes to be fed-back into real-time monitoring and coordination for all-round round smooth operation.

You can use any of the below 5 PLC Modules for industrial automation done in an efficient way.

PLC Modules for Industrial AutomationThere is no shortage of options out there when looking at the most appropriate PLC modules. Today, we will talk about 5 PLC modules for you.getOutputStream ()iliar.

Siemens S7-1200 - Build for versatility, this PLC module is has a lot of configuration possibility and various communication ports embedded making it the perfect choice for industrial automation applications ranging from small to complex ones.

Allen-Bradley CompactLogix- This PLC module is well-groomed for complex automation solutions due to its speedy processing features and modern diagnosis tools.

Mitsubishi Q Series - Its high-speed scanning and other quality aspects make this PLC module impossible to beat when automation calls for highest performance.

Omron CP1E : This PLC module is widely used for small & medium-grade automation systems as fast-processing speeds with flexible programming allow the users to implement desired functions rapidly.

For automation processes within the food and beverage industry, try this PLC module with an easy-to-use interface, as it is equipped with advanced security options. Schneider Electric Modicon M241

Advantages of Using PLC Modules for Controlling Industrial Systems

There are many benefits of integrating PLC modules with industrial control systems. Mainly, they provide monitoring and control of machinery, processes and systems in real-time which improves productivity by reducing downtime. PLC modules also allow for remote monitoring and control, a key requirement in many industrial applications. Operators can easily connect to and administer systems from specially optimized computer or mobile interfaces, even off-site. This flexibility provides operators with the ability to quickly solve potential problems.

A further major advantage of adopting PLC modules is that they can easily be integrated with other elements from the factory automation services including human-machine interfaces (HMIs), sensors, and other types of industrial machinery. Integrated here, this enables easy data access and analysis - to be able to tweak performance with proactive issue identification + adjustments.

As we know, the PLC modules are also types of equipment which can have a problem with its work. If the maintenance operations are so smooth, it would be great to fix problems before downtime happens! Troubleshootingfor PLC modulesThe followingare some troubleshooting tips for operating with PC Modules:

Voltage supply:-Has it the correct voltage for the unit is design to run on1.2 Devoid of any physical damage

Inspect the program code to ensure its correctness and see if any other problem resides in it that has been causing these disruptions.

Look for fault codes because errors are usually latched on message blocks of numerous PLC modules. Refer to your manufacturer's troubleshooter guidance.

How to Choose PLC Module for Your Industrial Requirements

There are many different factors to consider when choosing a PLC module for your industrial process. These factors encompass processing speed, input/output (I/O) capabilities, communication options and scalability. Selecting a PLC module that is compatible with your existing equipment and systems if of equal importance.

Developments in PLC Modules Follow Progress of Industrial Automation Below are some of the most significant PLC module advancements expected to become popular in 2021:

Artificial Intelligence (AI) Implementation- Applying AI to improve operations and productivity.

Cybersecurity Upgrades: Enhancing industrial systems to shield them from today's latest cyber threats.

Cloud Connectivity: Enable monitoring and control of you application form anywhere in the world.

Predictive Maintenance - Applying data processing to forecast when an equipment breaks down.

In summary, PLC modules are the irreplaceable part of industrial automation in present time. They provide live monitoring and control, can be used for remote operations,, work well with other systems and equipment in an industrial process,and bring number of advantages to technical operation management. With proper selection of PLC module to the needs, fast troubleshooting and healthy monitoring with all you will keep up-to- date on news technologies for more successfully production.

Huaqingjun a renowned industrial control manufacturer. company, following 20 years of rapid growth now enterprise of 3000 square meters that focuses on manufacture, development and sales Internet Things. We also have an R D department that can offer technical solutions customers. company also provides 4G module, Ethernet modules, WIFI modules, Bluetooth Modules, Simple Programmable PLC Integrated Machines, RS485 plc module Modules Industrial Relay Modules PLC AC/DC Power Amplifier Modules as well as additional core products.

product development has secured many patents. company has been awarded distinctions like "National High-tech Expertise", "Guangdong Province Contract-abiding Enterprise" "Creditworthy Enterprise". The products have been accredited by the "IS09001-2015 quality certification" and have also been able to pass other certifications, such as FCC and CE. The company gathered large number of experienced R D talents with backgrounds in professional academics such as electronic engineering, plc module engineering communication engineering, and more. team of experts works closely with their customers improve the overall experience for customers. They also serve large numbers of companies as well as manufacturers equipment. We create more competitive industrial solutions our customers. company has a highly skilled intelligent production facility. All products come with solid and well-established chips that guarantee top performance. Customers are able to use and buy with confidence.

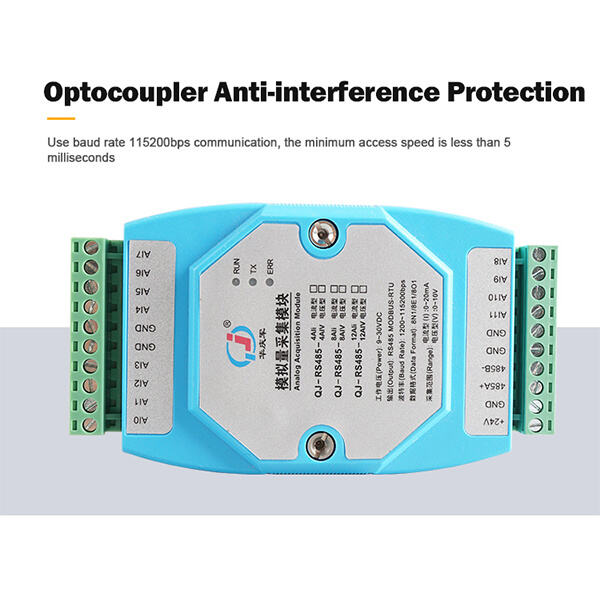

products comprise RS485 The products of RS485 232 Ethernet modules and analog inputs modules PLC, analog outputs module, HMI, relay module, AC/DC amplifier board as well as switching power supply. There are numerous applications parking systems, such as. The greenhouse ETC Induction, packaging system. plc module lighting system. streetlamp control. smart home system. Robot control. Control of water spray. The production line features SMT mounter equipped with automatic wave soldering automated packaging machines. The line also comes with complete set of quality control equipment. This ensures that each product is produced "carefully and professionally" to allow customers to buy and use the product with confidence. We are able to provide various options to meet the needs of the systems of our customers.

The company has a range patent that are national in scope has also received honors such as "National High Technology Expertise" and "Guangdong Province Contract-abiding and a Credit-abiding enterprise". The products have been certified "IS09001 2015 Quality Certification". product has also received CE, ROHS, FCC, SGS etc. certifications. company has also gathered an impressive pool R D talent with academic backgrounds in automation, electronics engineering, and communication engineering. team is dedicated to serving the needs customers by improving customer service plc module with the majority of Internet of Things and equipment manufacturing companies.