A timer in a PLC ladder diagram can simplify manufacturing operations. In today's article, we will introduce the concept of timers which are very useful devices that can help in managing timing of specific events related to manufacturing process we would be learning how timers can be used in a PLC ladder logic with examples.

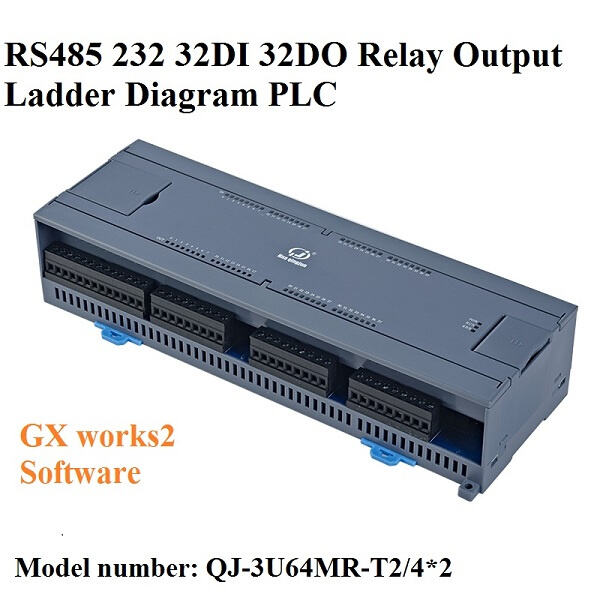

For example, let us say you wish to control the timing of a conveyor belt on your workshop floor. If you are able to program this into your Huaqingjun 4-Channel RS485 Communication Relay Module Modbus RTU Remote Control DO Modules for PLC Ladder diagram and tie it to a timer in order to stop the conveyor belt when time has reach that destination. This will help reduce bottlenecks in your production line and keep products flowing smoothly through the plant.

Timers in a warehouse can control the timing of packaging machines, for instance. Employees do not have to keep watching the process and can be rest assured that all packages are being sealed and labeled at the right time by giving out timers in your PLC ladder diagram. It will help you to boost your wholesale operations efficiency and cut down on your operating costs.

Timers can guide the timing of heating and cooling systems in a manufacturing plant, for instance. You can use these timers in a PLC ladder diagram so that the plant maintains its temperature without the need of manual intervention into it. This can enhance the performance of energy, which will save you money when it comes to maintaining the structure in good conditions.

As an example, timers can help to dictate when robotic arms move on a production line. A PLC ladder diagram has been prepared with timers to program the speed and order of movement of these robotic arms so, which results in better quality finished goods. This will decrease the chance of waste and rework in your manufacturing, thus saving costs and profits.

We live in a fast-paced business world where the race to beat the competition is important for survival. You can maintain your competitive position in your industry by making use of timers in your PLC ladder diagrams to ensure that your production processes will run more efficiently and work more effectively.

Timers, for instance, can be used in warehouse inventory management systems to time exactly when that system is working. Implementing timers within your PLC ladder diagram means you can monitor your stock levels and restock accordingly, reducing the risk of running out of stock meaning lost sales. It is good for keeping a competitive advantage in front of market and bring customers to your wholesale operations.